Have you perhaps already thought about a customised case? Take a look at the 3 most exciting case projects of the last few months. You can find more case examples on the page special cases for sensor technology. Or simply ask for a non-binding consultation.

Case with WOW effect:

Customer requirement:

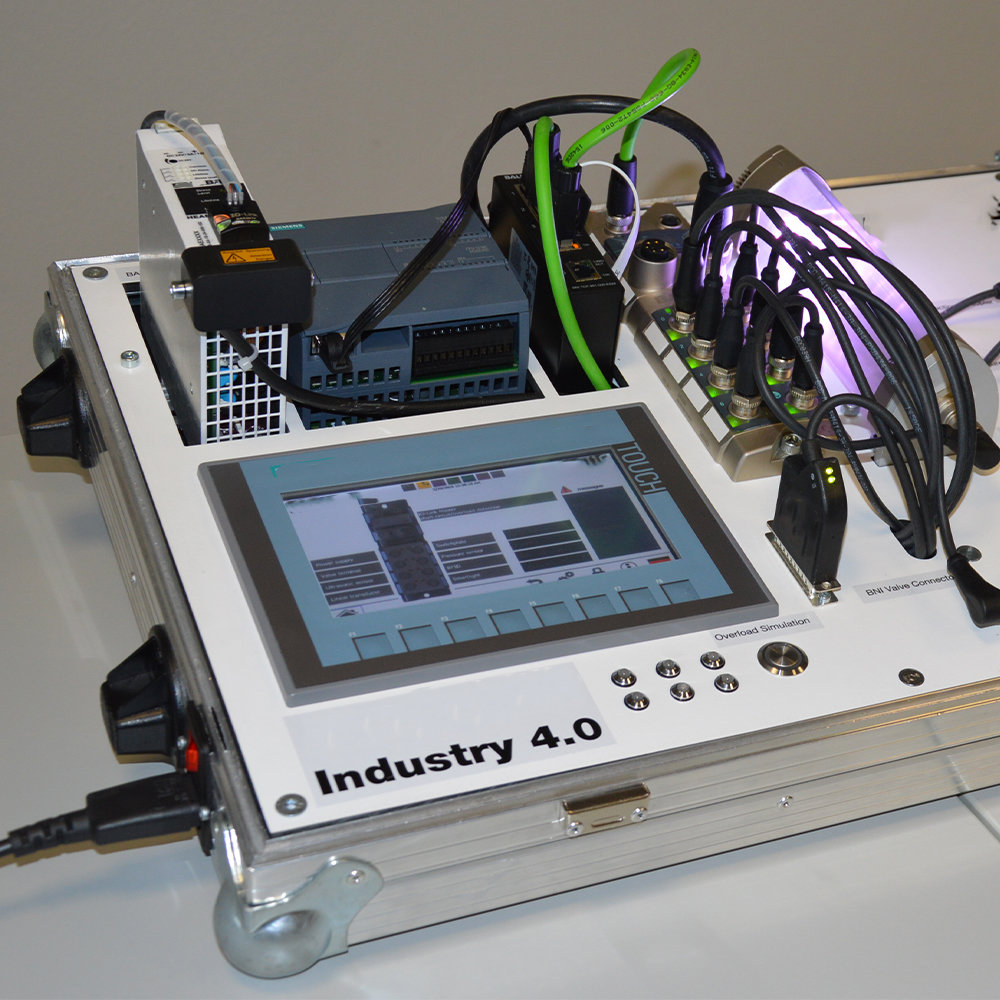

How do I get my interested party to engage with the product as long as possible? That was our client’s consideration. A test set-up that is as realistic as possible should help. The prospective customer should have the opportunity to test the system himself. But how can electronic data first be collected and then still be transferred to the cloud if no extensive technical equipment is available?

Solution of bwh:

We received several kinds of electronic components from the customer for the test setup, such as the sensor, a fan and also a WLAN module for data transmission. Based on the chosen case type “Supreme AES“, a case has been developed that can accommodate everything without any problems. Inside, unsightly cabling and unimportant parts disappear under a plate. The remaining components are well protected in a foam insert. To start the test, all you have to do is plug in the connector and you’re ready to go!

Mobile sensor test:

Customer requirement:

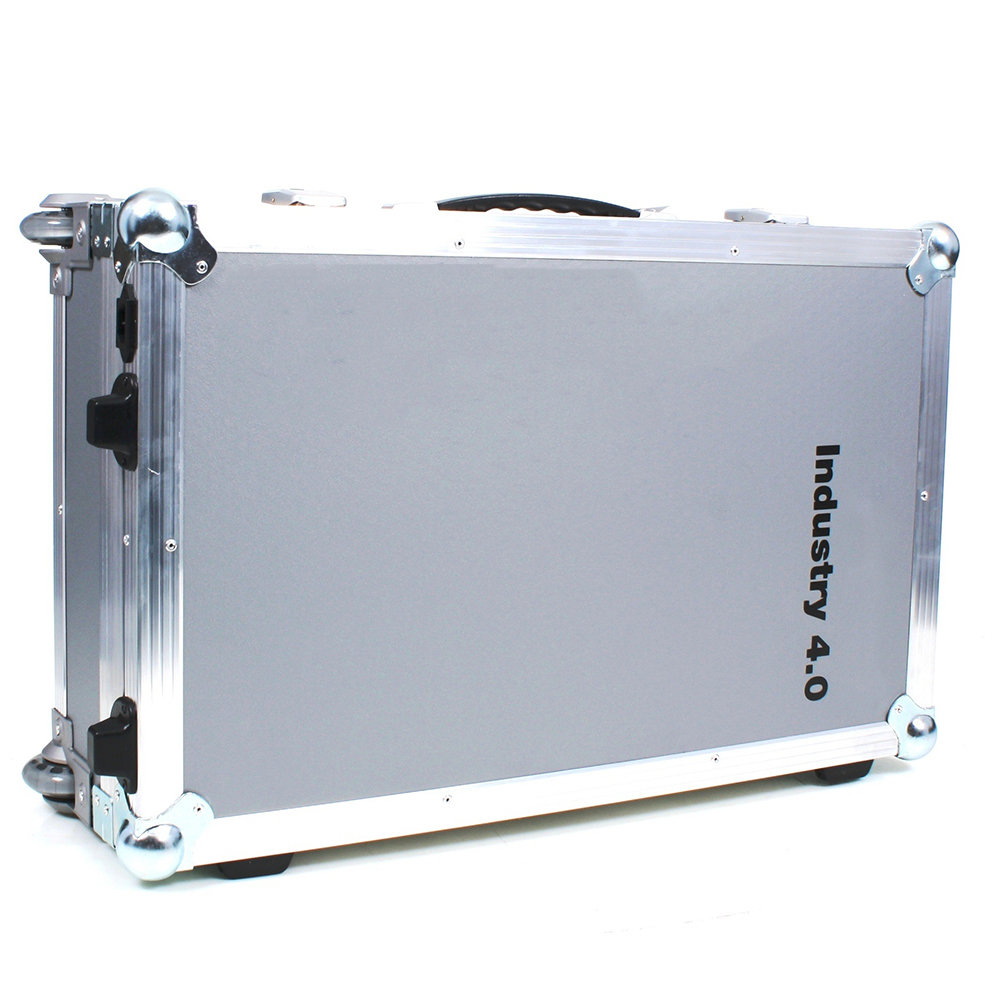

How can the functioning of sensors be presented without the complete relevant technology being available? A complete test station with a lot of high-tech is therefore to be built into a case. The requirements are high. The technology must be well protected and at the same time easy to transport.

Solution of bwh:

The individual aluminium case is tailored exactly to the required parts. This keeps the test station small and compact. The case lid can be completely removed. Therefore, the prospective customer has a good overview of the electronics inside. Everything is clearly arranged on a plate. The cabling is hidden underneath. With the built-in power connector, the whole system comes to life. The prospective customer can thus test all functions in detail and get advice from the sales representative.

A trolley handle and rollers make the case easy to transport. The robust construction keeps the expensive electronics well protected. A logo print rounds off the overall picture. The sales team is therefore well equipped to create a true product experience.

Protection for expensive equipment:

Customer requirement:

Often, not only the sensor technology is needed for measurement, but also all kinds of accessories. But how can all this be transported together without damage?

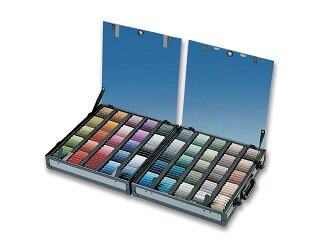

Solution of bwh:

With the help of an individual case and a foam insert, all components of the set are clearly stowed away. Through an optimal arrangement, the entire volume of the case is utilised. This makes the case very compact. The foam inside is cut to fit the individual parts. Each part has its place and is reliably protected. At first glance, you can already see if something is missing. Thanks to the case, you make a professional impression in front of your customer.

If parts of the set change, a new foam insert can easily be cut and inserted. This makes the case very sustainable.

Are you curious to learn more?

We would be pleased to advise you free of charge and without obligation, so that your (case) wishes can come true!