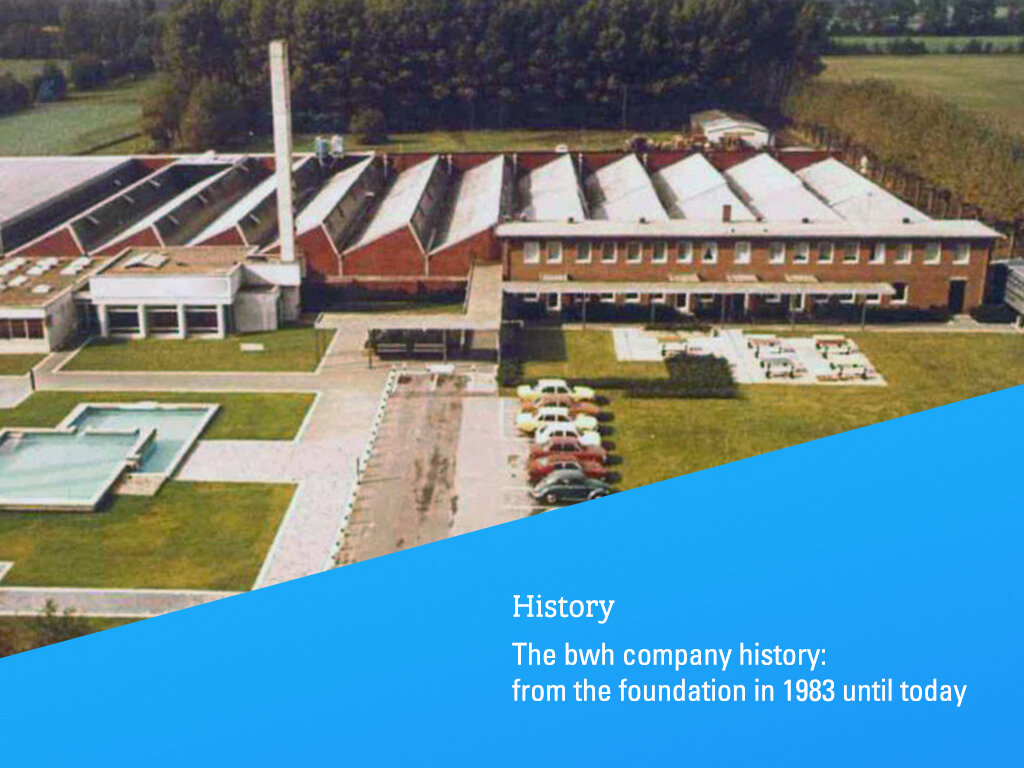

History: The bwh company history from its foundation in 1983 to the present day

We are bwh Koffer – our company history is a success story of more than 40 years of innovation and pioneering spirit. As global leader in the manufacture of special cases, we owe our success to one principle: we find the right solution for every customer requirement.

Our journey to becoming the market leader for individual case solutions began in 1983 with the founding of the company. Innovation and quality have always been our focus. Our individual “Made in Germany” case solutions require know-how and technical understanding. Today, we are proud to be part of the Westphalian region and to continue researching sustainable products. Thanks to our dedicated employees, we are ideally equipped for future challenges.

Take a look at the exciting milestones in over 40 years of bwh history:

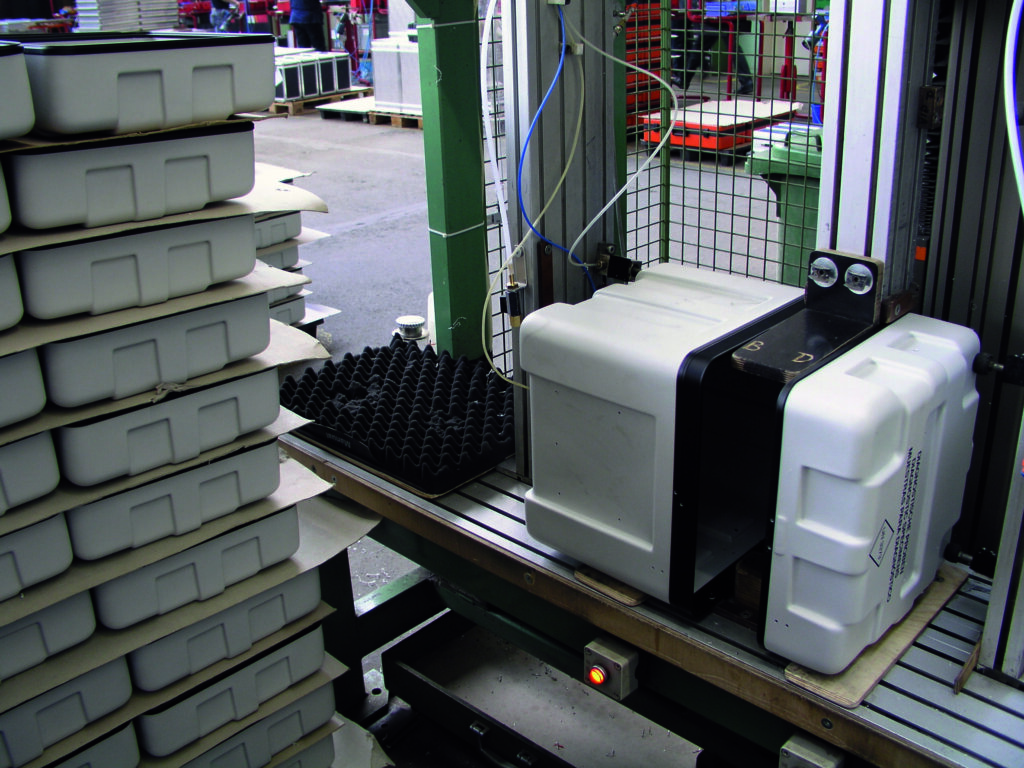

For the first time, CNC-controlled drilling and milling machines are used in case production, guaranteeing high precision.

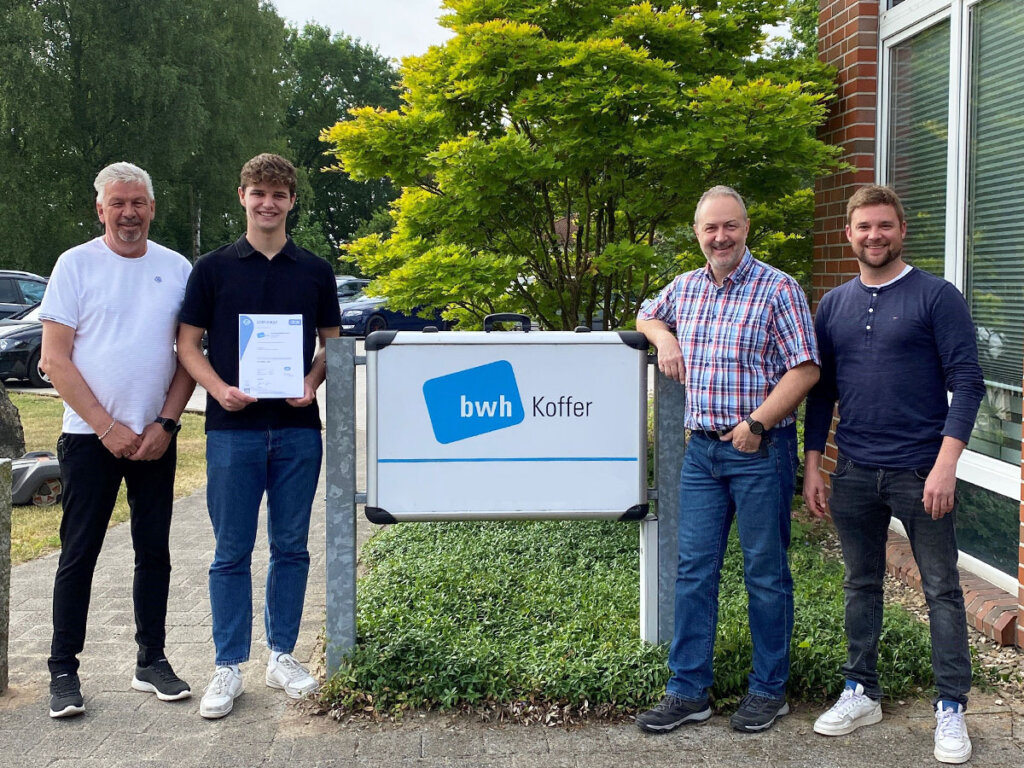

bwh Koffer is certified according to DIN ISO 9001 for the first time. From now on, the company’s high quality standards are reflected in its certified quality management.

bwh Koffer conquers the internet: the company’s website goes online for the first time

bwh Koffer founds its subsidiary, B+W Koffermarkt GmbH & Co. KG. At the beginning, only cases from the bwh standard line are sold through the online shop www.koffermarkt.com.

In cooperation with Transguard, a company of the Emirates Group, the Sky Box is being developed as a transport solution for the air cargo sector.

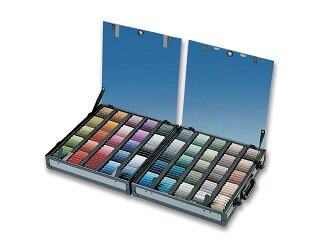

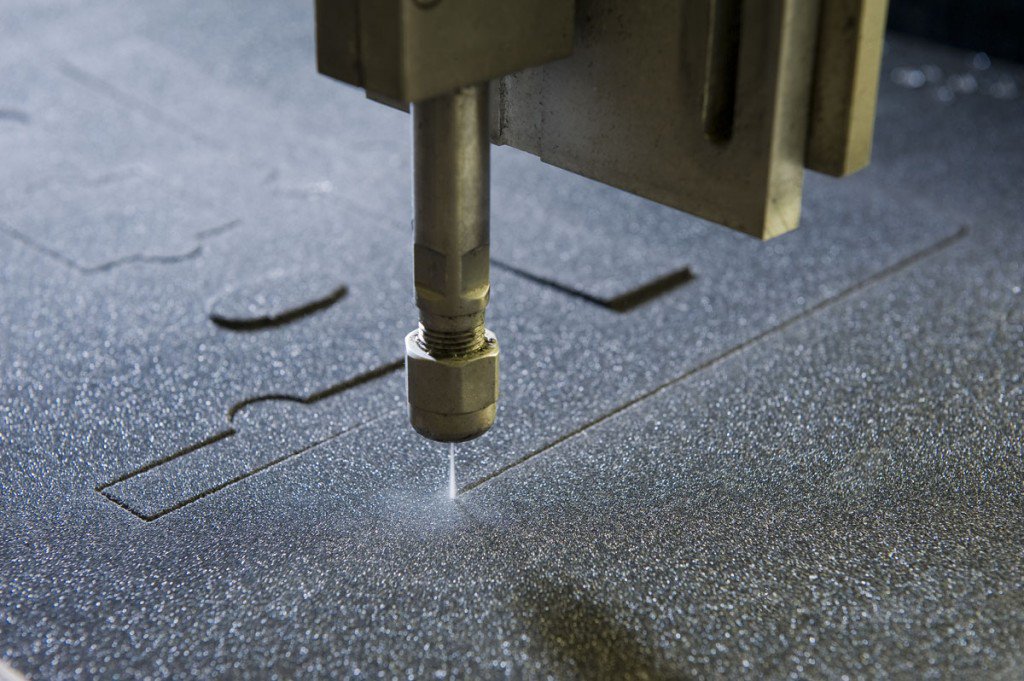

The production of foam inserts is now carried out with the help of a waterjet cutting machine. This enables the in-house production of individual foam inserts according to customer requirements.

bwh Koffer develops the new AZKR aluminium case series. The case body made of hard-wearing material with all-round aluminium profiles and angles offers reliable protection and a great design.

The bwh experts develop the foldable and collapsible Variosafe Box: the space-saving transport box is particularly suitable for one-way shipping.

Certification of the Casys Box by TÜV Rheinland according to IP 54 (dust and splash-proof) and IP 67 (dust and waterproof)

The online shop www.koffermarkt.com is being completely redesigned. In addition to a new visual appearance, travel cases and bags from renowned brand manufacturers will be offered from now on.

The previously nameless stadium of the local sports club FC Stella Bevergern is given the official name bwh Stadion to mark the club’s 100th anniversary.

Development and introduction of the Guardian Case: the robust plastic case is the perfect transport case for rough work use

The new production hall for foam processing at the Hörstel-Bevergern site is opened and now offers around 650 m2 of additional space for our production.

The case experts at bwh have developed the Robust Case, a sturdy aluminium frame case with particularly robust impact protection corners.

The security of the Sky Box and the Casys Box is enhanced by the new electronic pylocx locking system. The lock is 100% tamper-proof.

bwh Koffer is once again revising its website, which is now also optimised for viewing via smartphone or tablet.

Launch of the bwh case foam configurator, an online configurator for individual case foam inserts.

Development and introduction of the almost silent bwh whisper castors and the bwh pull-out handle, which ensures maximum transport comfort.

bwh celebrates the production of the five millionth case since the company was founded. Thanks go to our employees and to our loyal customers, who have made this success story possible.

The T Box transport case series convinced the expert jury of the pro-K Award with its robust and splash-proof construction as well as its integrated heavy-duty castors. The jury’s verdict could be summarised briefly and succinctly with the following sentence: “Protected safe transport!”

At the beginning of the pandemic, masks are a scarce commodity. bwh Koffer provides an employee to sew cloth masks for several weeks. The mouth-nose masks are donated to the city of Hörstel and social institutions.

We are now taking our case production one step further towards sustainability: thanks to the environmentally friendly material Sea Plastics, which is obtained from maritime waste and broken fishing nets, our case shells can be made from up to 100% recycled material. We are the first case manufacturer to source and process materials from this environmentally friendly source.

We are pleased about the commissioning of the now second large photovoltaic system on the roofs of our production halls. With our own photovoltaic system, we now produce part of our daily electricity consumption ourselves.

bwh Koffer celebrates its 40th anniversary this year. 40 years have flown by… We are proud to be one of the leading suppliers of special suitcases in the world today. Together with our employees and business partners, we are celebrating this success in a fitting manner.

With the case configurator, bwh Spezialkoffer is expanding its digital offering. Customers can individually configure selected case solutions and order them directly online.

bwh Spezialkoffer is introducing a certified environmental management system in accordance with ISO 14001. This underlines the company’s long-term commitment to sustainable and resource-saving processes.